Sorry for the late reply guys. Also, I didn't take any photos, as my hands were constantly full of grease.

However, this guy did:

http://www.patrol4x4.com/forum/showthre ... t=cv+joint

- FAexpl.JPG (97.72 KiB) Viewed 8262 times

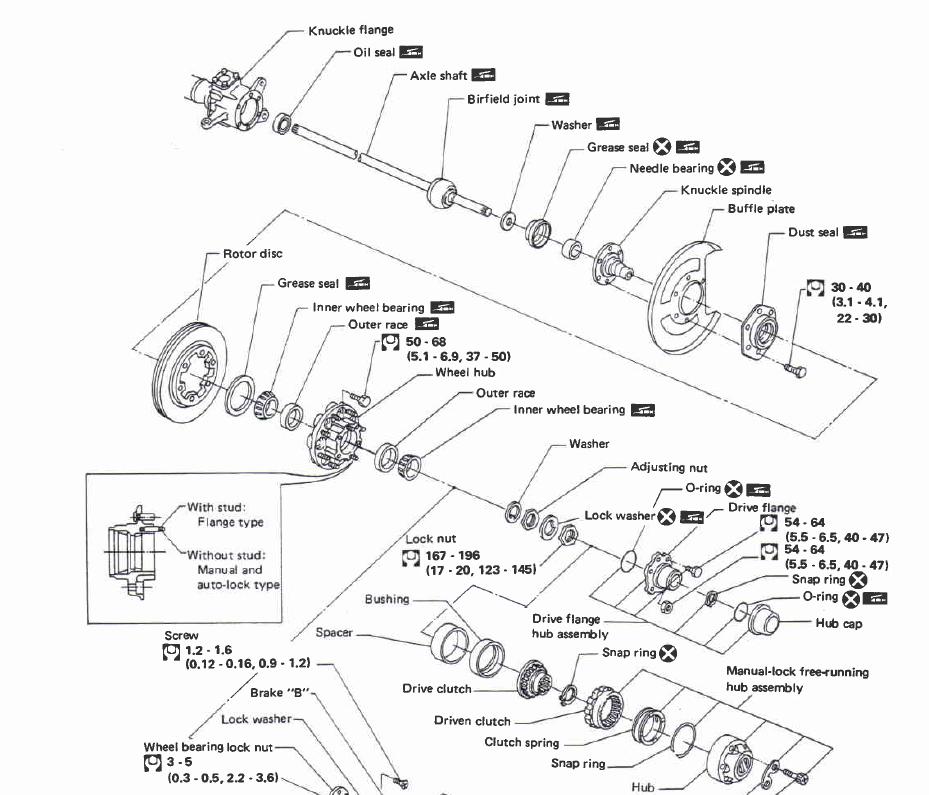

There are three seals that will need to be replaced if you do this job and grease the wheelbearings, and none of the three seem to be available from the

bearing specialists.

The inner oil seal (top row, second item in drawing) seems to be a specialist

part which I have not managed to source elsewhere. It is 34 x 44 x 8mm and Nissan's

part number is N405330J00.

The grease seal on the inside of the knuckle flange (top row item 6) and the grease seal on the inside of the

wheel hub (second row second item) are also Nissan-only. The

part numbers are N4023201J00 and N40227C8200 (not sure which is which)

Of the bearings in the assembly, only one is special. This is the inner or large

wheel bearing (second row third and fourth items). It is a KOYO 33110JRYA2. This is a standard 33110JR taper roller

bearing (85 x 50 x 26mm) but the inner corner which presses against the knuckle spindle has had the radius ground to 4.5mm. This can be sourced through Nissan (about R830.00), special import through

Bearing International (R902.00) or you can buy a standard 33110JR (R280)and have the corner ground by an engineering shop (about R200-250?).

The outer

wheel bearing (second row items 6 & 7) is a standard imperial-sized taper roller

bearing, 41.275 x 73.431 x 23.012mm. Koyo

part numbers are: Cone LM501349, Cup LM501311.

The needle roller

bearing (first row, item 7) is a 42 x 35 x 16mm, KOYO

part number BTM3516.

I did not remove the knuckle bearings.

There was one other problem though: There is a lock washer between the two

wheel bearing nuts (second row, item10), which is bent to keep the two nuts from turning. This washer must be replaced because the tab which fits into the groove in the knuckle flange is damaged when you remove it. My local Nissan agents were entirely unsucsesful in identifying this

part, and after three weeks of ordering one wrong

part after another I finally made my own. I modified the design to have two much more substantial tabs bent into the slots, in the hope that in this way it will be re-usable although it would still be better to replace them. The drawing is available for anybody who wants it.

Please note that the abovementioned washer is only used in the manual locking hub assembly, the automatic hub appears to have a different system.

All the above

part numbers are for the petrol-engined Y60 patrols, and I am not sure twhether the Y61's are the same. I do know that the Birfield joints are not the same in the Y60 as in the Y61, as the Y61's are larger diameter with flats to allow removal but the Y60's don't have these flats.